Description

Professional Soundproofing That Actually Works

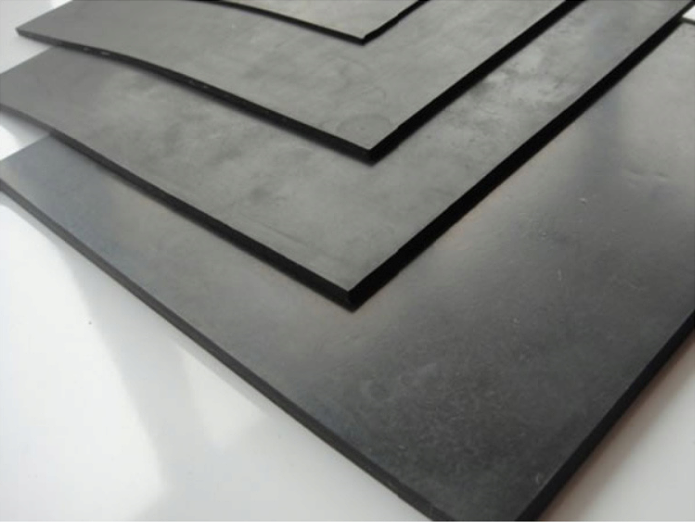

Eliminate unwanted noise with our High-Density Soundproofing Rubber Sheet. Engineered for maximum acoustic absorption, this heavy-duty polymer-based matting delivers superior noise reduction for factories, studios, workshops, and industrial environments - reducing sound transmission by up to 60dB.

Why Choose Our Soundproofing Rubber?

- Superior Noise Reduction: High-density polymer construction blocks and absorbs sound waves - up to 60dB reduction

- Heavy Duty Construction: Extra-thick, high-mass material provides maximum acoustic deadening performance

- Versatile Applications: Perfect for walls, floors, ceilings, machinery enclosures, and equipment isolation

- Easy Installation: Cut to size and fix with adhesive or mechanical fixings - no specialist tools required

- Durable & Long-Lasting: Resistant to oils, chemicals, and temperature extremes - maintains performance for years

- Cost-Effective Solution: Professional-grade soundproofing at a fraction of the cost of acoustic foam or specialist panels

- Custom Sizes: Sold per linear metre - order exactly what you need

Technical Specifications

- Material: High-Density Polymer-Based Rubber Compound

- Density: 1400-1600 kg/m³ (extra heavy for maximum sound blocking)

- Thickness Options: 3mm, 5mm, 10mm, 12mm

- Width: 1m or 1.4m rolls

- Length: Sold per linear metre - custom cut available

- Colour: Black

- Sound Reduction: Up to 30dB depending on thickness and installation

- Temperature Range: -30°C to +80°C

- Chemical Resistance: Resistant to oils, greases, and mild chemicals

Perfect For:

- Industrial: Factory floors, machinery enclosures, production areas, workshops

- Music & Recording: Recording studios, practice rooms, home studios, rehearsal spaces

- Automotive: Vehicle sound deadening, engine bays, wheel arches, doors

- Commercial: Offices, meeting rooms, call centres, restaurants

- Residential: Home theatres, music rooms, apartments, party walls

- HVAC: Ductwork, air handling units, pump rooms, plant rooms

How Soundproofing Rubber Works

Sound travels through vibrations. Our high-density rubber sheet works by adding mass to surfaces, which reduces their ability to vibrate and transmit sound. The polymer-based construction also absorbs sound energy, converting it to minimal heat rather than allowing it to pass through. This dual-action approach delivers superior noise reduction compared to lightweight acoustic foams.

✓ Up to 60dB Noise Reduction | ✓ High-Density Construction | ✓ Easy to Install | ✓ Free UK Delivery

Installation Guide

Surface Preparation: Clean surface thoroughly, removing dust, grease, and loose material. Ensure surface is dry.

Cutting: Measure carefully and cut to size using a sharp Stanley knife and straight edge. For thick sheets, score deeply and bend to snap.

Fixing: Apply acoustic sealant or contact adhesive to back of sheet. Press firmly into place, working out air bubbles. For heavy sheets or ceiling applications, use mechanical fixings (screws with large washers) in addition to adhesive.

Sealing: Seal all edges and seams with acoustic sealant to prevent sound leakage.

Performance Tips

- Thicker sheets provide better sound reduction - use 10mm+ for maximum performance

- Cover as much surface area as possible - gaps allow sound to leak through

- Combine with other acoustic treatments (foam, panels) for best results

- For machinery, create complete enclosures rather than partial coverage

Care & Maintenance

Once installed, soundproofing rubber requires no maintenance. Expected lifespan: 20+ years in most applications.

Expert Advice Available

Not sure which thickness or how much you need? Our acoustic specialists can help you calculate the right solution for your specific noise problem. Contact us for free expert guidance.